Kemtrak Photometer DCP007-VIS

DESCRIPTION

Kemtrak - 'It is a leading manufacturer of fiber optic instrumentation and automation products for process applications.

Conventional-photometers use mercury photometers, which continuously expose samples to a wide range of radiation and heat generated by mercury lamps. This has negative consequences for both the equipment. A more efficient and market proven technology is the Kemtrak DCP007.

The Kemtrak DCP007-VIS flow analyzer is a high-performance fiber optic photometer for measuring concentrations of substances in solutions in real time with high resolution.

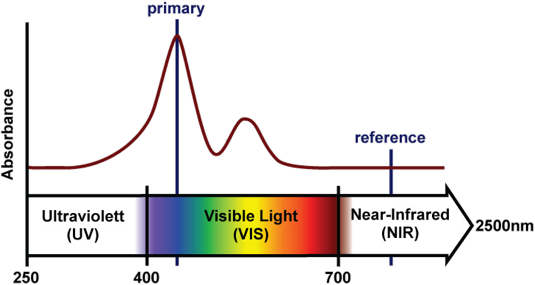

The Kemtrak DCP007 UV photometer measures two wavelengths. A primary "absorbing" wavelength is used to measure the observed substance, and a "non-absorbing" reference wavelength is used to compensate for turbidity, air bubbles and/or contamination.

Light sources can easily be replaced on Kemtrak DCP007 photometers and the configuration changed to measure other desired wavelengths. The Kemtrak DCP007-VIS operates in wavelength ranges from 250 to 1050 nm and if a liquid or gas has an optical density in this range, the Kemtrak DCP007-VIS can measure it

Kemtrak offers customized solutions to meet the needs of a wide range of industries, including:

- Chemical

- Petrochemical

- Biotechnological

- Pharmaceutical

- Food, Pulp and Paper

- Municipal and Environmental

Kemtrak DCP007 technology allows you to accurately measure components such as:

Acetone

Calcium carbonate

Copper

Ozone

Alcohols

Chlorine

Hypochlorite

Phosgene

Benzene

Chlorine Dioxide

Nickel

Cadmium

Bromine

Chromium

Nickel

Cobalt

Iodine

Oils

Hydrocarbons

Acids

And many others...

Examples of Applications:

ASTM D 156 - Seybolt Scale

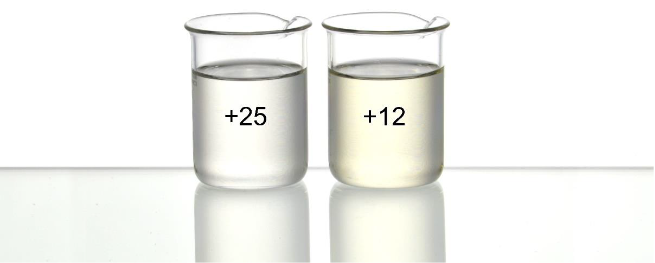

The Saybolt color scale has traditionally relied on the comparison of a standard color disk viewed through an adjustable sample volume. This dimensional color scale is subject to bias by erroneous operator decisions. Kemtrak DCP007 technology standardizes and automates the processes used to evaluate Saybolt Scale products.

ASTM D 1500

The ASTM D 1500 color scale is applicable to a wide range of petroleum products, such as lubricating oils, heating oils, diesel fuels and waxes. The ASTM D 1500 color scale is the primary quality measurement used for the purchase, and sale of partially refined oils.

As the oil is refined, there is a correlation between the color of the distillate and the degree of refining. During the refining process, crude oils have evolved into an assortment of products with distinct colors ranging from dark red to black to pale yellow tinged lighter fractions. Distinctively colored petroleum subducts can be accurately measured and defined using the ASTM D color scale.

The ASTM D 1500 color scale is also used for product and interface identification and for product contamination monitoring.

All of these can be determined by Kemtrak DCP007-VIS technology.

Light Source

High-performance VIS emitting light-emitting diode (LED)

Wavelength range: 360 - 1100 nm

Full-width half maximum (FWHM): 10 nm

Center Wavelength Accuracy (CWL): ± 1 nm

Typical lamp life:

- 360 - 400 nm: > 30,000 hours

- 400 nm: > 100,000 hours

Note:

- Measuring wavelengths must be set at the factory

- Typical specifications for 500 nm light source

Photodetector

Silicon photodiode

Photometric range

At 500 nm, 10 mm OPL: 0 - 5 AU

Photometric accuracy

At.

1 AU, 25 °C: 0.001 AU

2 AU, 25 °C: 0.001 AU

3 AU, 25 °C: 0.01 AU

4 AU, 25 °C: 0.1 AU

Photometric noise

At.

1 AU, 250 - 1100 nm: 0.0001 AU

2 AU, 250 - 1100 nm: 0.001 AU

Z AU, 250 - 1100 nm 0.01 AU

4 AU, 250 - 1100 nm: 0.1 AU

Linearity

± 0.5 % of the respective measuring range (is specific for certain measurements)

Contact us for more information / suggestions.

— Тегін Сайттар мен CRM.

— Тегін Сайттар мен CRM.